Our smelter network —

an overview

Maximum metal extraction

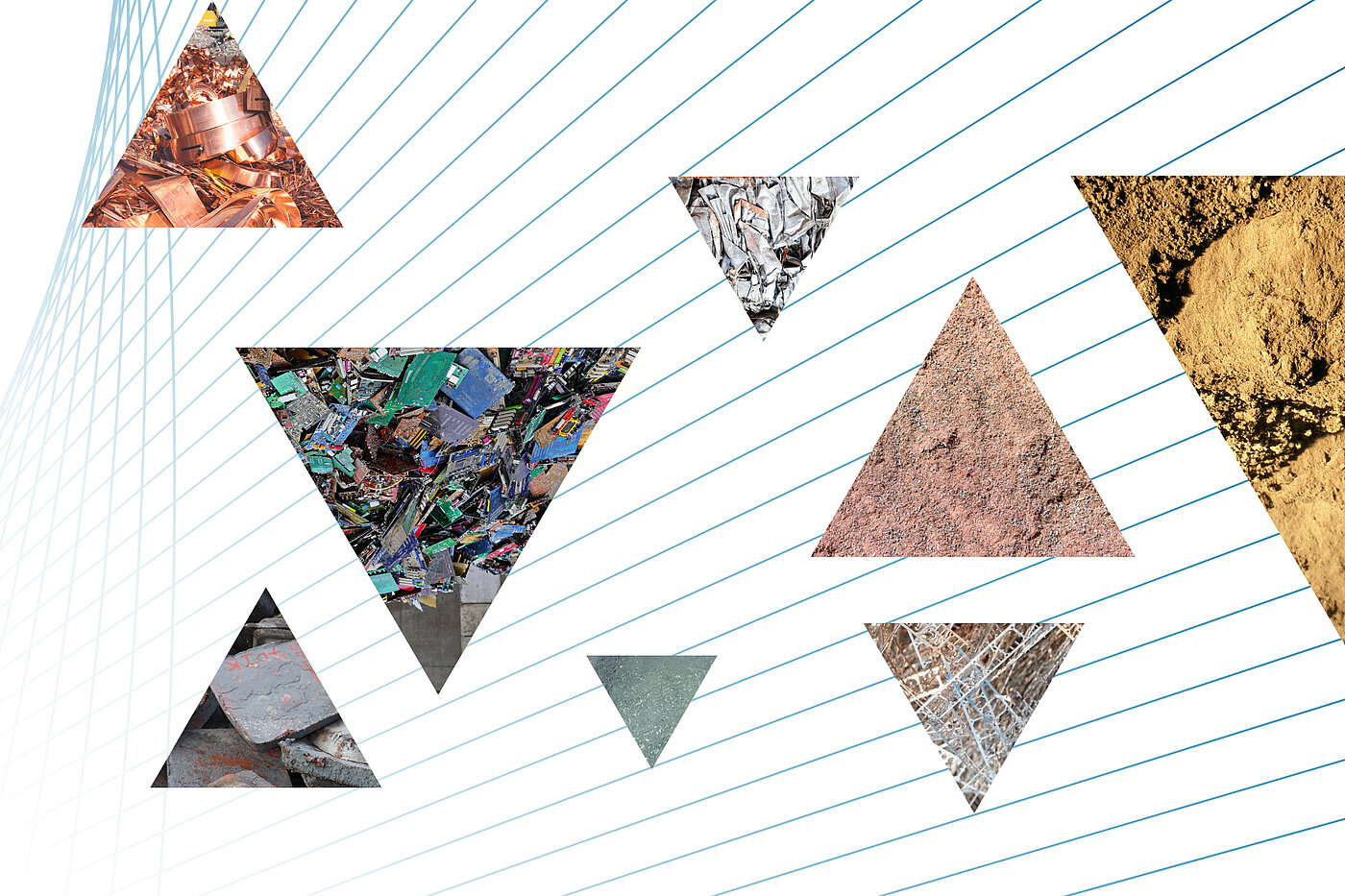

We produce a variety of metals of the highest quality with our integrated smelter network — efficiently and sustainably. Our metal processing comprises three major processing steps in the value chain:

- Concentrates that contain copper

- Concentrates that contain precious metals/nickel

- Scrap metal

- Alloy scrap

- Electronic scrap

- Industrial residues

- Slimes and dusts

- Copper and copper-nickel electrolysis

- Copper processing

- Precious metal refining

- Intermediate product processing

- Additional, non-precious metal processing

- Antimony

- Bismuth

- Copper

- Gold

- Iron silicate

- Lead

- Nickel

- Platinum metals

- Selenium

- Silver

- Tellurium

- Tin

- Zinc

- Sulfuric acid

Smelting

At our smelter sites, we process concentrates that contain copper and precious metals along with a wide range of organic and inorganic recycling raw materials. This generates the first intermediate product, copper anodes of differing metal compositions, which are the basis for downstream processing steps.

Refining

In our tankhouses, we refine the anodes into high-purity copper cathodes — according to their composition. Industrial and precious metals are separated out, along with a number of other metals. In this processing step, metals like nickel, lead, tin, gold and silver collect in intermediate products like anode slimes and electrolyte, which serve as starting materials for the extraction of multiple metals.

Multimetal

We use additional, bought-in intermediate products to process our starting materials into marketable metals and products in this step. Our metallurgical expertise allows us to extract a number of metals from raw materials efficiently and responsibly. They create the foundation for the green transformation, technologies of the future like electric cars, and many industrial applications.

Strength lies in diversity

Collaboration and experience transfer, synergies and innovations — the central elements of the modern working world are nothing new for Aurubis. Quite the opposite, in fact. We have always practiced them. Our core strength lies in our unique structure: a globally integrated network of copper smelters, recycling sites, and highly specialized metal processing plants.

A network backed by the expertise of more than 7,200 employees worldwide. Thanks to the unique structure and enormous pool of knowledge, we can process a range of very different materials efficiently and profitably — from copper concentrates and complex recycling materials to production scrap and customer waste.

The foundation of success

We turn all these materials into metals that can be directly used in new products. Solar panels, wind turbines, electric cars, energy storage plants, power lines, data networks: Aurubis metals are in almost everything that makes our lives sustainable and digital — tomorrow and today. Our metals serve as the foundation for an innovative, environmentally friendly world. Just like our powerful smelter network is the foundation of our success. But we’re not resting on our laurels. We continue to optimize and expand our network with projects that target long-term growth. With one clear objective: to consolidate and continually expand our powerful position as one of the most efficient and sustainable multimetal producers in the world.

Specific strengths

Aurubis has six copper smelter sites: Hamburg and Lünen in Germany, Pirdop in Bulgaria, Olen and Beerse in Belgium, Berango in Spain. All these smelters process copper-rich raw materials into high-purity copper cathodes. They are not identical, though — each site works with individual processes and has specific strengths. Pirdop is purely a primary smelter and processes the most copper concentrates in the largest smelter furnace in the Aurubis Group. Along with concentrates, the Hamburg plant also uses recycling materials. Lünen, on the other hand, is a pure recycling specialist and employs a range of materials — including intermediate products from other sites. The same is true for Olen. In recent years, the plant has continually upped the proportion of recycling materials and works very agilely to cast the right anodes for other Aurubis plants. The Berango plant processes less high-grade recycling materials and feeds what the other Aurubis plants can’t use into its production, including metal-bearing slags. Beerse rounds out the network with a number of special processes, including a vacuum technique for extracting tin and lead from all kinds of recycling materials. A perfect combination for Aurubis, since lead is an important component in copper production.

3 questions for

Christian Plitzko

Supply Chain Management, Group Metallurgy

What makes the Aurubis network so special?

Christian Plitzko Only a few metal companies in the world have our degree of vertical integration, from the raw material to the copper product, plus our broad spectrum of value generation. We extract 20 elements in addition to copper! Our great strength is our ability to process a mix of so many different, complex raw materials and extract and recover so many metals at the same time.

How do the individual sites profit from the network?

Every site has its own specific strengths and unique qualities, and no one site has to try and cover everything. Each leverages its expertise to achieve the highest metal yield or recovery. This includes passing intermediate products, like anode slime, on in the network to be processed by the plant with the highest efficiency.

What do you think the future holds?

We want to meet the rising demand for metals as sustainably as possible by increasing recycling. So we have to adjust and advance our processes again and again as raw materials change. We are also pushing the electrification of our processes and using alternative fuels. All this gets Aurubis even closer to our goal: carbon-neutral metal production.

In our smelter network, we process a broad variety of multimetal recycling materials, find solutions to metallurgical challenges, and make a crucial contribution to the circular economy.

Using everything

All the smelters in the network deliver their anode slime, a valuable copper production waste product, to Hamburg. The metals and precious metals contained in the slime are extracted there, and the precious metal smelter processes the latter to silver, gold and other metals. Hamburg is also where intermediate products that cannot be sold are turned into products that can go back into internal manufacturing processes or sold on as new products. Sulfuric acid, a by-product generated when copper concentrates are processed and crucial for the fertilizer and chemical industries, is produced in our Hamburg and Pirdop plants. There is even a plant for processing selenium, a semi-metal contained in concentrates: Aurubis subsidiary RETORTE transforms the waste material into highly valuable compounds for a range of applications. An impressive number of Aurubis sites, seven all told, turn our main product, the copper cathode, into products like wire rod and continuous cast shapes.

Metals recovered in FY 2022/23

~920 t silver

~7,850 t tin

~50 t selenium

3 questions for

Dirk Vandenberghe

Managing Director Olen, Beerse, and Berango

What makes the Aurubis network special?

Dirk Vandenberghe Adaptability is one of its strengths. Over the past decades, the network was systematically adapted with each growth stage. And we bring loose ends in the smelter network closer together with every strategic project. We methodically integrate specific strengths and technologies to broaden our position. That s how we re moving forward!

How has the network changed?

Now that the Beerse and Berango sites, which I m responsible for along with Olen, have been integrated, we can cover the entire portfolio of recycling materials available on the market. And these sites have brought another key skill into the network: the refining of pure tin. Material flows in the Group were optimized accordingly to maximize tin production.

What do you think the future holds?

We’ll continue to systematically expand and improve the network and build our capacities for specific metals like nickel with the BOB project in Olen. And we ll also be able to process those intermediate products we now sell internally, thanks to projects like ASPA in Beerse. This adds more value for Aurubis as a whole — and preserves our independence.

True innovations

No one site does it all, and each capitalizes on its specific expertise, while working together to form a cohesive whole. The result: the utmost in synergies and efficiency. This approach allows us to close material loops and recover many new substances from a range of different raw materials. And the network model ensures consistently stable material flows. The sites help each other out with raw materials and final products, and in unusual situations, making sure no bottlenecks occur. The differences work together to drive our innovative power: New ideas and true innovations emerge from the interplay of a variety of perspectives, and wide range of expertise.

Aurubis’ unique strength lies in our great diversity. A strength we will continue to build on with our investment projects and clear course set for carbon-neutral production. Generating more metals together, responsibly, to increase the sustainability of life on our planet. This mission unites us all.